Celebrating the Capital Region’s Manufacturing Industries

As Manufacturing Day is celebrated this Oct. 5, it is important to remember that while large manufacturers, such as General Electric, GLOBALFOUNDRIES and Regeneron Pharmaceuticals, have helped turn the Capital Region into a thriving manufacturing metro, they are not alone in making the area stand out on the national level. In fact, these manufacturers operate in only a third of manufacturing industries in which the Capital Region has concentrations of employees above the national average, according to a Center for Economic Growth (CEG) analysis of data from Economic Modeling Statistics Inc. (EMSI).

Location Quotient

The Capital Region has a dozen manufacturing industries1 with a location quotient (LQ) above 1. An LQ of 1 indicates a region’s share of employment in a particular industry is equal to that of the nation. According to EMSI, “industry LQ is a way of quantifying how ‘concentrated’ an industry is in a region compared to a larger geographic area, such as the state or nation.” It is calculated by “comparing the industry’s share of regional employment with its share of national employment.”

Highly Concentrated Regional Industries

For an industry to register an above-average concentration of employees (LQ>1), it does not necessarily need to have thousands of employees. Having such large numbers certainly helps but does not guarantee an LQ above 1. For example, with an LQ of 8.05 and 2,835 employees in 2017, Engine, Turbine, and Power Transmission Equipment Manufacturing was the Capital region’s most concentrated manufacturing industry. However, the Bakeries and Tortilla Manufacturing had 1,023 employees in 2017, but its LQ was .90.

The below table details the Capital Region manufacturing industries with nationally significant concentrations of employees.

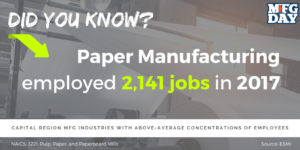

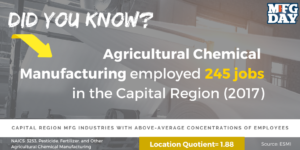

For more details on some of the Capital Region’s lesser known, highly concentrated manufacturing industries, see the below infographics:

|

|

CEG Activities to Support Industry Growth

Several initiatives are currently underway to ensure the Capital Region’s talent pipeline can meet the demands of manufacturers. They include:

• Construction of the Gene F. Haas Center for Advanced Manufacturing Skills (CAMS) at Hudson Valley Community College (HVCC), a $14.5 million, 37,000 square foot building dedicated to providing hands-on training to machinists, toolmakers, industrial maintenance technicians and other skilled technical workers.

• CEG recently received $250,000 from KeyBank to support the below manufacturing training programs:

» Expansion of HVCC’s Manufacturing Technology Pathways Project, a short-term, stackable credential training program, or “boot camp,”

» Launch of the Certified Production Technician (CPT) program at Schenectady County Community College (SCCC). The CPT program is an eight- to 12-week-long certificate course that is intended to skill-up incumbent workers who are looking to advance their career, or enhance the education of an unemployed or underemployed person who possesses some manufacturing experience.

• Expansion of CEG’s Manufacturing Intermediary Apprenticeship Program (MIAP) to assist local manufacturers in training workers for high-skill trades.

• CEG’s Business Growth Solutions (BGS offers technical services to help Capital Region manufacturers with optimal improvement, strategic growth, sustainability and energy efficiency, and technology acceleration.

Notes

1 Four-digit North American Industry Classification System (NAICS) code industries.

Don’t miss these insights into the trends that are shaping the Capital Region’s economy. Sign up for CEG’s e-news and follow us on: