The Research Connection – September 2019: Advanced Materials Edition

Featured R&D projects:

- Startup aims to advance the 3D printing of high-performance ceramics

- Binghamton to acquire advanced materials research tool

- Using nanotechnology to optimize ceramics, alloys, and composites

- Exploring the properties of photonic nanostructures

- Bio-industrial Materials Institute (BMI): Sustainable Materials Development

- Mycelium based biocomposites and foams

- High efficiency fiber reinforced isogrid structures

- New Materials Support Next Generation Clean Energy Systems

- Using Nanoglue to Make Composites Several Times Tougher During Dynamic Loading

- Easy to Make Surface-Eroding Polyanhydrides for Biomedical Applications

- Product Design and Engineering of Advanced Polymer Composites

This edition’s contributors: SUNY Research Foundation | SUNY Polytechnic Institute |University at Albany | Binghamton University |Union College |Clarkson University |Rensselaer Polytechnic Institute

Startup aims to advance the 3D printing of high-performance ceramics

Description: Lithoz America is the first ceramic additive manufacturing company to establish a U.S. presence. The startup, the North American subsidiary of its Vienna-based holding company, chose the Capital Region for its startup-friendly environment and strong framework of resources, according to Shawn Allan, vice president of Lithoz America. The company worked with the UAlbany Innovation Center to launch operations in Troy, and it is a certified business in Innovate 518, a NYSTAR Innovation Hot Spot. Lithoz America is the world leader in producing systems and materials for additive manufacturing of precision advanced ceramics suited for industrial and medical use. The company also produces custom ceramic/resin compositions and performs feasibility and development projects for customers. Collaborate with Lithoz America or learn more about partnering with the University at Albany.

Potential applications: Medical implants, dental implants and restorations, aerospace technologies.

Contact: Matt Grattan, Director of Economic Development, mgrattan@albany.edu

Binghamton to acquire advanced materials research tool

Description: Binghamton University will acquire a sophisticated new X-ray tool useful in materials research and R&D for electronics. The $1.75M HArd X-ray Photoelectron Spectroscopy (HAXPES) system — the first of its kind in the U.S. — will be housed in the Institute for Materials Research at Binghamton. HAXPES requires a powerful source of X-rays and an extremely sensitive detector. The techniques associated with it have been used for about a decade, but they previously were only possible with a synchrotron — a kind of particle accelerator that generates X-rays. At those facilities, visiting scientists typically conduct experiments over a period of hours and then leave. HAXPES will provide synchrotron-comparable data in a laboratory setting, which makes it much more forgiving in terms of time and much more useful for private industry. Collaborate with the research team or partner with Binghamton University.

Description: Binghamton University will acquire a sophisticated new X-ray tool useful in materials research and R&D for electronics. The $1.75M HArd X-ray Photoelectron Spectroscopy (HAXPES) system — the first of its kind in the U.S. — will be housed in the Institute for Materials Research at Binghamton. HAXPES requires a powerful source of X-rays and an extremely sensitive detector. The techniques associated with it have been used for about a decade, but they previously were only possible with a synchrotron — a kind of particle accelerator that generates X-rays. At those facilities, visiting scientists typically conduct experiments over a period of hours and then leave. HAXPES will provide synchrotron-comparable data in a laboratory setting, which makes it much more forgiving in terms of time and much more useful for private industry. Collaborate with the research team or partner with Binghamton University.

Potential Applications: Batteries, next-generation electronics, neuromorphic computing, and solar energy harvesting.

Contact: Louis Piper, Institute for Materials Research Director, lpiper@binghamton.edu

Using nanotechnology to optimize ceramics, alloys, and composites

Description: SUNY Poly Professor Kathy Dunn and her research team are using photons, electrons and ions to uncover relationships between crystalline defects and chemical inhomogeneities in advanced materials. This effort has significant relevance to the Chemical Mechanical Planarization (CMP) process in the semiconductor manufacturing flow, where it is important to avoid defects in the final products. The Dunn group explores how nanoparticle size, size distribution and surface chemistry change with use conditions, and how these changes impact the removal rate and surface quality of the polished wafer.

Description: SUNY Poly Professor Kathy Dunn and her research team are using photons, electrons and ions to uncover relationships between crystalline defects and chemical inhomogeneities in advanced materials. This effort has significant relevance to the Chemical Mechanical Planarization (CMP) process in the semiconductor manufacturing flow, where it is important to avoid defects in the final products. The Dunn group explores how nanoparticle size, size distribution and surface chemistry change with use conditions, and how these changes impact the removal rate and surface quality of the polished wafer.

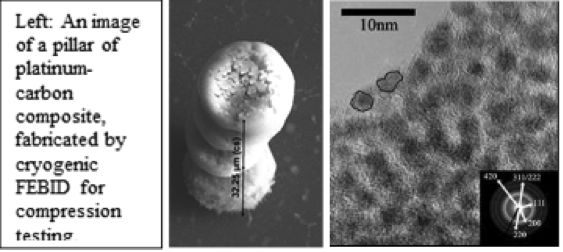

Manipulating matter at length scales approaching atomic is also critical for enabling many nanotechnology applications in additive nano-manufacturing, plasmonics and biomedicine. The Dunn Group is developing methods for depositing metals and composites with controlled nanostructure and composition by Focused Electron Beam Induced Deposition (FEBID) that address the technique’s two Achilles’ heels: low growth rates and low purity of the deposited material. Support this research and its expansion into other metals/alloys or collaborate with the research team.

Potential Applications: New slurries for an improved CMP process; nano-structured metal alloys in additive nano-manufacturing, fuel cells, and integrated circuits.

Contact: Kathy Dunn, Associate Professor, kdunn1@sunypoly.edu

Exploring the properties of photonic nanostructures

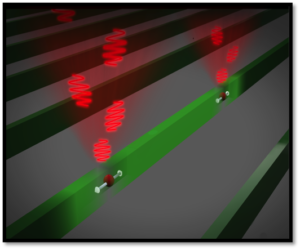

Description: The light emitted by a single-photon emitter is fundamentally different from laser or thermally produced light. The key distinction relates to the time intervals between the emitted photons in the light beam. Photons can either cluster together in bunches or they can have regular gaps between them. In the latter case, an ion cannot emit two photons at once, which can lead to a non-classical light (single-photon emission) source. This is a required property for the development of future quantum optoelectronics and long-distance quantum communication applications using existing fiber-optical-based infrastructures. At SUNY Poly, Professor Spyros Gallis is leading research that aims to develop material platforms for quantum light sources at telecom wavelengths. In particular, the research is examining critical optical properties of erbium ions, enabled by a new class of SiC nanophotonic structures for telecom quantum-optical networks. Support this research or collaborate with the research team.

Description: The light emitted by a single-photon emitter is fundamentally different from laser or thermally produced light. The key distinction relates to the time intervals between the emitted photons in the light beam. Photons can either cluster together in bunches or they can have regular gaps between them. In the latter case, an ion cannot emit two photons at once, which can lead to a non-classical light (single-photon emission) source. This is a required property for the development of future quantum optoelectronics and long-distance quantum communication applications using existing fiber-optical-based infrastructures. At SUNY Poly, Professor Spyros Gallis is leading research that aims to develop material platforms for quantum light sources at telecom wavelengths. In particular, the research is examining critical optical properties of erbium ions, enabled by a new class of SiC nanophotonic structures for telecom quantum-optical networks. Support this research or collaborate with the research team.

Potential Applications: Nanowire-based sensing, quantum sources, quantum photonics, and long-distance quantum communications.

Contact: Assistant Professor Spyros Gallis, sgalis@sunypoly.edu

Bio-industrial Materials Institute (BMI): Sustainable Materials Development

Description: Plant-based bio-industrial materials have the ability to achieve the nexus of sustainability by offering positive environmental, social and economic impacts. The BMI is a consortium of three schools (Union-RPI-SUNY New Paltz) developing the technologies needed to take commodity crops such as bast fiber plants and transform them into commercially viable engineering materials. These materials have specific properties that rival glass fiber composites without the perils associated with petrochemically based materials.

Description: Plant-based bio-industrial materials have the ability to achieve the nexus of sustainability by offering positive environmental, social and economic impacts. The BMI is a consortium of three schools (Union-RPI-SUNY New Paltz) developing the technologies needed to take commodity crops such as bast fiber plants and transform them into commercially viable engineering materials. These materials have specific properties that rival glass fiber composites without the perils associated with petrochemically based materials.

Potential applications: Structures, infrastructure, marine, automotive, sporting goods, furniture, etc. The ideal business partner would be a company with an existing fiberglass application looking for a more sustainable material alternative.

Contact: Ronald B. Bucinell, Department of Mechanical Engineering, bucinelr@union.edu

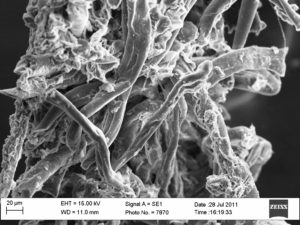

Mycelium based biocomposites and foams

Description: Fungal-based biopolymer matrix composites with lignocellulosic agricultural waste as the filler are a viable alternative for some applications of synthetic polymers. This research provides insight into the impact of the processing method and composition of agriwaste/fungal biopolymer composites on structure and mechanical properties. The morphological and mechanical characterization of bio-composites are being investigated with an integrated experimental and computational approach.

Description: Fungal-based biopolymer matrix composites with lignocellulosic agricultural waste as the filler are a viable alternative for some applications of synthetic polymers. This research provides insight into the impact of the processing method and composition of agriwaste/fungal biopolymer composites on structure and mechanical properties. The morphological and mechanical characterization of bio-composites are being investigated with an integrated experimental and computational approach.

Potential applications: Replacement for Styrofoam

Contact: Ronald B. Bucinell, Department of Mechanical Engineering, bucinelr@union.edu

High efficiency fiber reinforced isogrid structures

Description: Fiber-reinforced isogrid structures are made up of a lattice or ribs oriented in an equilateral configuration that give the structure extremely efficient characteristics. This configuration takes advantage of the highly directional properties of fiber reinforced materials. Fiber reinforced isogrids have specific structural properties that are hundreds of times greater than their metal counterparts.

Description: Fiber-reinforced isogrid structures are made up of a lattice or ribs oriented in an equilateral configuration that give the structure extremely efficient characteristics. This configuration takes advantage of the highly directional properties of fiber reinforced materials. Fiber reinforced isogrids have specific structural properties that are hundreds of times greater than their metal counterparts.

Potential applications: Satellites, rockets, aircraft, marine structures, buildings.

These structures would be attractive to companies that are involved with high performance structures.

Contact: Ronald B. Bucinell, Department of Mechanical Engineering, bucinelr@union.edu

New Materials Support Next Generation Clean Energy Systems

Description: Chulsung Bae, a professor of chemistry and chemical biology at RPI, focuses on the development of functional organic/polymeric materials for special applications, particularly for clean energy and environment technologies. His lab is developing ion-conducting polymer materials gas separation polymer membranes for applications in next generation energy conversion and storage technologies like fuel cells, hydrogen production via water splitting devices, and redox flow batteries.

Description: Chulsung Bae, a professor of chemistry and chemical biology at RPI, focuses on the development of functional organic/polymeric materials for special applications, particularly for clean energy and environment technologies. His lab is developing ion-conducting polymer materials gas separation polymer membranes for applications in next generation energy conversion and storage technologies like fuel cells, hydrogen production via water splitting devices, and redox flow batteries.

Potential applications: fuel cells, batteries

Contact: Reeve Hamilton, Director of Media Relations, hamilr5@rpi.edu

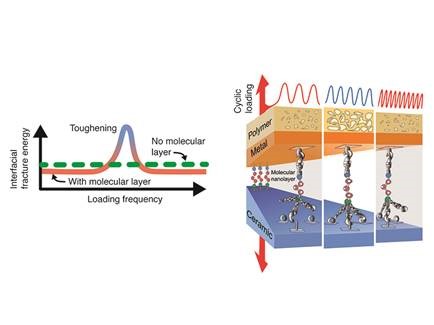

Using Nanoglue to Make Composites Several Times Tougher During Dynamic Loading

Description: In a discovery that could pave the way for new materials and applications, Ganpati Ramanath, a John Tod Horton Professor of Materials Science and Engineering at RPI, and other materials scientists found that oscillating loads at certain frequencies can lead to several-fold increases in the strength of composites with an interface that is modified by a molecular layer of “nanoglue,” The use of nanoglue was pioneered at RPI, and this discovery opens up an entirely new set of possibilities to design composites with novel responses using different combinations of polymers and interfacial nanolayers.

Description: In a discovery that could pave the way for new materials and applications, Ganpati Ramanath, a John Tod Horton Professor of Materials Science and Engineering at RPI, and other materials scientists found that oscillating loads at certain frequencies can lead to several-fold increases in the strength of composites with an interface that is modified by a molecular layer of “nanoglue,” The use of nanoglue was pioneered at RPI, and this discovery opens up an entirely new set of possibilities to design composites with novel responses using different combinations of polymers and interfacial nanolayers.

Contact: Reeve Hamilton, Director of Media Relations, hamilr5@rpi.edu

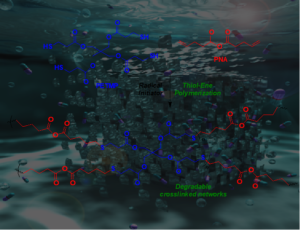

Easy to Make Surface-Eroding Polyanhydrides for Biomedical Applications

Description: There is an increasing need for new materials that are both biocompatible and biodegradable for medical use, particularly for drug delivery, therapeutic devices and gene therapy/delivery. This patented work helps address this need through the development of a novel method to synthesize polyanhydrides, which are a class of surface eroding polymers that maintain their mechanical integrity during degradation and exhibit a gradual loss in size. The new process uses thiol-ene chemistry, a step-growth mechanism of polymerization. Through this process, it is possible to produce materials that are elastomeric, photocurable and have controllable degradation rates, starting from only several hours.

Description: There is an increasing need for new materials that are both biocompatible and biodegradable for medical use, particularly for drug delivery, therapeutic devices and gene therapy/delivery. This patented work helps address this need through the development of a novel method to synthesize polyanhydrides, which are a class of surface eroding polymers that maintain their mechanical integrity during degradation and exhibit a gradual loss in size. The new process uses thiol-ene chemistry, a step-growth mechanism of polymerization. Through this process, it is possible to produce materials that are elastomeric, photocurable and have controllable degradation rates, starting from only several hours.

The team is interested in collaborating with practitioners in these areas for implementing and commercializing the technology. The patent (# US 10,280,263 B1) describing the innovation are available for licensing and other opportunities.

Potential applications: Biomedical devices, degradable adhesives, drug delivery vehicles.

Contact: Devon A. Shipp, dshipp@clarkson.edu

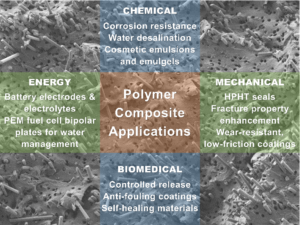

Product Design and Engineering of Advanced Polymer Composites

Description: Polymer composites are multiphase soft matter systems that play a critical role in diverse chemical, electrochemical, mechanical and biomedical applications. Research on these materials is centered around the dynamic properties and interfacial interactions between the different phases in the system. The design, synthesis and processing techniques are developed with attention to green engineering, scale-up and commercialization aspects, and the materials are characterized using a variety of advanced characterization techniques. This research would be highly relevant to companies developing and marketing products such as HPHT seals and coatings for aggressive chemical environments, anti-corrosion paints, CMP polishing pads and slurries, adhesives, cosmetics, pharmaceuticals, biomaterials, fuel cells, batteries, supercapacitors, and membranes for electrochemical water purification technologies.

Description: Polymer composites are multiphase soft matter systems that play a critical role in diverse chemical, electrochemical, mechanical and biomedical applications. Research on these materials is centered around the dynamic properties and interfacial interactions between the different phases in the system. The design, synthesis and processing techniques are developed with attention to green engineering, scale-up and commercialization aspects, and the materials are characterized using a variety of advanced characterization techniques. This research would be highly relevant to companies developing and marketing products such as HPHT seals and coatings for aggressive chemical environments, anti-corrosion paints, CMP polishing pads and slurries, adhesives, cosmetics, pharmaceuticals, biomaterials, fuel cells, batteries, supercapacitors, and membranes for electrochemical water purification technologies.

Potential applications: The technical staff of interested organizations are invited to collaborate with Dr. Krishnan on focused and timely R&D in a broad range of product design applications involving polymers. The Krishnan group has a good track record of collaborative research and successful application of chemical and materials engineering fundamentals, to practical problems, leading to product improvement, innovation, and IP development.

Contact: Sitaraman Krishnan, skrishna@clarkson.edu

About The Research Connection: The Research Connection is a quarterly feature in the Center for Economic Growth’s monthly, online newsletter, The CEG Indicator. This special feature highlights R&D being conducted by researchers at Capital Region colleges and universities and others throughout the SUNY system. The Research Connection spotlights academic R&D in CEG’s focus technology sectors: Nanotechnology and Semiconductors, Cleantech/Energy, Biotechnology, Advanced Materials, Population Health Technology and Information Technology.

Each edition of The Research Connection will highlight several research projects in a specific technology sector. The Research Connection will keep CEG investors (2,500+) and CEG Indicator subscribers (9,000+) informed on the cutting-edge R&D that is being conducted by SUNY and other academic researchers that could potentially transform their industries. It will also encourage collaboration, patent, licensing and other opportunities.

Don’t miss these insights into the trends that are shaping the Capital Region’s economy. Sign up for CEG’s e-news and follow us on: